Important Safety Information

Important Safety Information

« Click Here

Testing the safety valve

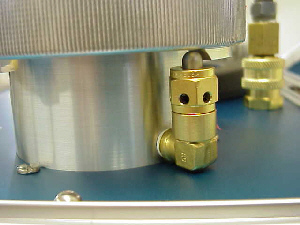

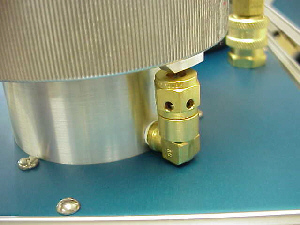

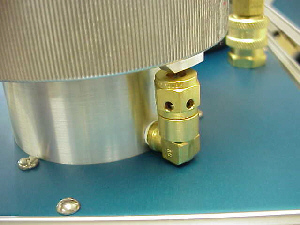

Instruments with a lug-type cover have a safety valve (located at the back on the right side of the chamber body). Model 650 does not have or need this valve. This valve vents the chamber if the cover is not completely closed. This valve MUST be tested at the beginning of each measurement session.

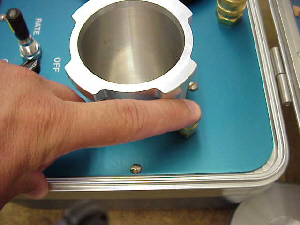

First, use your finger to depress the piston so that it is inside the safety valve

Insert a solid rubber gasket into the cover

Install the cover on the chamber body

Turn the chamber all the way to the stop so that the cam is over the piston

Then turn the lid back so that the cam is not blocking the piston

Begin to slowly apply pressure to the chamber (The rate valve should be nearly closed)

The safety valve should pop open before the pressure reaches 2 bar.

You will hear nitrogen escaping from the valve and the pressure will not increase in the chamber If it does not, turn the control to EXHAUST, then remove the nut and piston of the safety valve and lubricate the O-ring on the piston with petroleum jelly. Reassemble and test the safety valve again. When the safety valve opens, the pressure in the chamber should drop to near zero.

This time the safety valve should open at a pressure below 2 bar. If it does not, remove the nut and piston of the safety valve and again clean and lubricate the O-ring on the piston with petroleum jelly. Check for any foreign debris then reassemble and test the safety valve again.

The safety valve is an important safety component of the instrument. Do not attempt to operate the instrument until the safety valve is operating properly; that is, until it is releasing the chamber pressure at less than 2 bar pressure.

As an added safety precaution, the cover should be left in only one of two positions:

- on the chamber and completely locked in place, or

- completely removed from the chamber.

The cover should never be left in any intermediate position. This section on safety valves does not apply to chambers with a threaded cover (i.e. Model 650) as there is no danger of the vessel being pressurized with the cover only partially installed.

Testing the Pressure Relief Valve

All instruments are fitted with a Pressure Relief Valve. This valve is set at the factory for the maximum operating pressure of the instrument. The valve will discharge pressure if the maximum operating pressure is exceeded.

This valve rarely needs any maintenance or testing. If you desire to test the Pressure Relief Valve you should do the following:

Insert a solid rubber gasket into the cover.

Install the cover on the chamber body

Turn the chamber all the way to the stop so that the cam is over the piston

Pressurize instrument to full operating pressure.

You will hear pressure discharge from valve located inside the instrument.

It might be necessary to completely exhaust the chamber before the safety valve resets.