Important Safety Information

Important Safety Information

« Click Here

The instrument requires very little maintenance other than general cleaning and lubrication. Be sure to keep chamber, O-rings and working parts free of dirt and debris.

Chamber Lid O-ring

Lubricate Chamber Lid O-ring daily when in regular use. Wipe all dirt and grit away from O-ring with a rag. Apply petroleum jelly to O-ring.

Small Sealing System O-rings and Washers

The small O-rings for sealing samples are Buna 40 O-rings. Keep O-rings and washers clean of debris. Use Buna 40 O-rings. Buna 70 (normal O-rings) are not soft enough for this application. If additional O-rings or washers are needed you can purchase them directly from PMS Instrument Company.

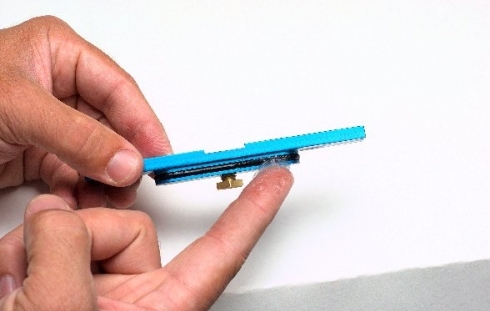

Large Sealing System

Occasionally remove the Compression Gland Screw by turning the screw counter-clockwise until it comes out of the lid. Remove the washer and Compression Gland Insert and take out the Compression Gland Gasket. Clean all parts and then re-assemble. Ensure to lubricate the threads of the Compression Gland Screw with a durable lubricant.

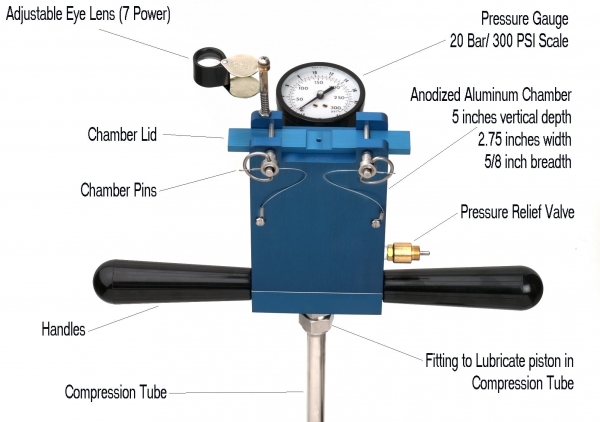

Adjustable Eye Lens

The Eye Lens needs no maintenance. However, ensure that the bolt stays firm in the aluminum chamber body. Use the stainless steel nut to keep it firm in the body. Focal point is adjusted by using the brass nut. Loosen to raise the lens and tighten to press it closer to the sample.

Gauge

No maintenance required. It is a 2.5 inch gauge with dual scales of 20 Bar/ 300 PSI. It is accurate to 1%.