Important Safety Information

Important Safety Information

« Click Here

The Piston inside the Compression Tube should be lubricated occasionally for optimal operation. Failure to properly lubricate the piston will cause excessive friction against the rubber piston cup and will eventually fail to pressurize chamber.

To access the Piston, loosen the stainless steel fitting at the base of the instrument. This is accomplished by loosening the outer nut (not by unthreading the fitting from the chamber). The piston should then be visible. Push the rod up and lubricate piston and also squeeze a small amount of lubrication under piston to lubricate all of Compression Tube. Cycle the piston through the Compression Tube and then repeat lubrication.

When re-assembling ensure Compression Tube is completely before tightening the fitting. Recommended lubrication is a lithium based grease such as “White Grease”. Piston rod should not be lubricated as it is not necessary and only draws dust and dirt into the Compression Tube.

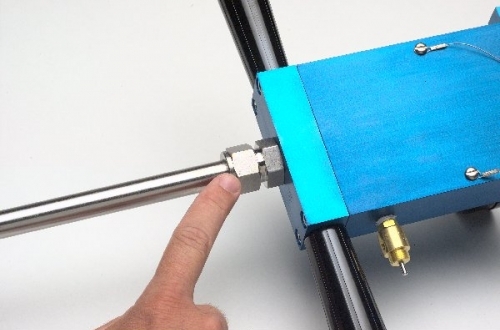

First, loosen the outer nut.

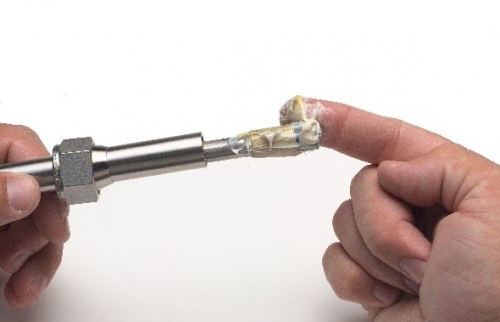

Second, push up piston and clean off old grease.

Next, apply lithium based grease.

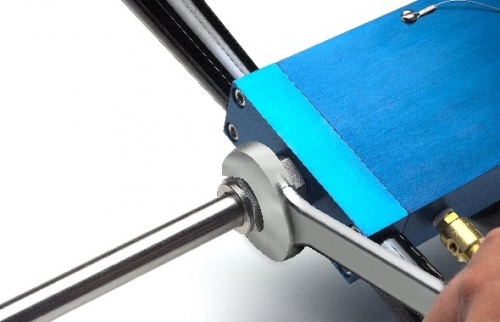

Cycle the piston through the Compression Tube.

Apply more grease.

Finally, push piston down into Compression Tube.

Slide Compression Tube back into the fitting.

Ensure it is all the way in and tighten the outer nut.

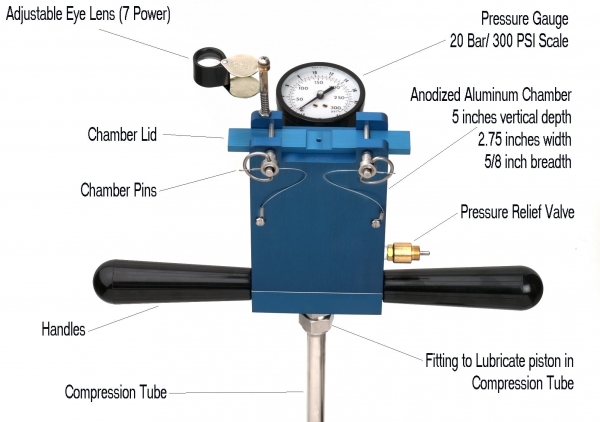

To identify the parts described above refer to photo below: