Important Safety Information

Important Safety Information

« Click Here

(Chamber will increase pressure each stroke, but will not hold pressure)

First, you need to bubble check the instrument. Prepare a mixture of water and a small amount of liquid soap in a cup and mix the soap into the water.

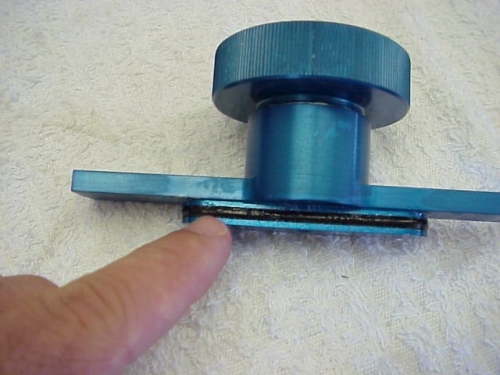

Next, you will need to pump the instrument up until it begins to leak. Do this by first inserting a leaf into the chamber lid so that it will be completely closed. Pump the instrument up and then begin to dribble the water/soap mixture on the following places to see if they are leaking. If you discover a consistant flow of bubbles, this indicates that there is a leak in this area.

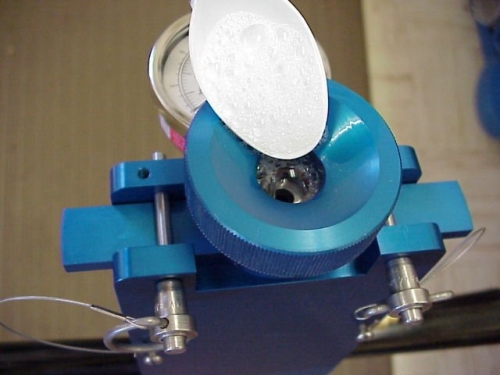

First, check the inside of the lid where the sample is sealed into the lid.

If leaking – tighten the Compression Screw tighter on the sample. Compression Gland Gasket might be worn and need replacement.

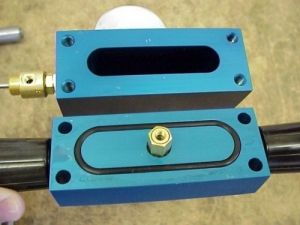

Next, check around the outside edge where the lid seals into the chamber.

If leaking – check the O-ring for wear, displacement or if the leaf sample has been caught between the O-ring and the chamber. Remove obstruction, re-set O-ring or replace O-ring. Lubricate O-ring with petroleum jelly.

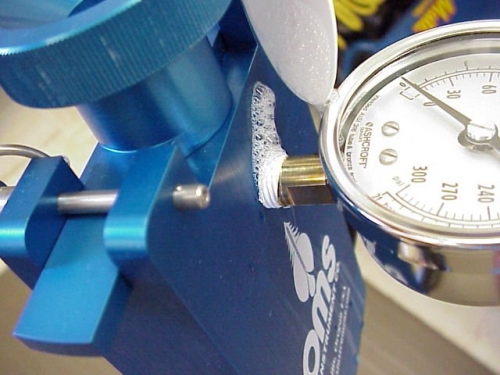

Next, check where the gauge screws into the chamber.

If leaking – remove the gauge carefully with a wrench. Clean threads on gauge and inside chamber carefully to ensure there is no debris. Re-tape the threads on the gauge and re-install on chamber.

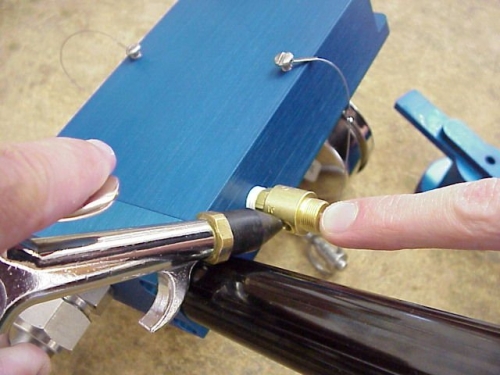

Next, check where the purge valve screws into the chamber. Dribble some fluid on the bottom side of the purge valve where the exhaust hole is.

If leaking around threads – remove the purge valve carefully with a wrench. Clean the threads on the purge valve and inside the chamber carefully to ensure there is no debris. Re-tape the threads on the purge valve and re-install on chamber with exhaust port pointing down.

If leaking through the exhaust port – There is most likely something obstructing the valve so it will not close. Use compressed air to blow in reverse into the chamber. Remove the lid of the chamber, depress the button on the purge valve and blow air in reverse into the chamber. This normally removes the debris.

Lastly, check the seam between the base of the chamber and the chamber itself.

If leaking – tighten the 4 stainless steel cap screws at the bottom of the chamber. If this does not fix the problem, remove the 4 cap screws so the O-ring is exposed. Remove the O-ring and clean it. Re-install. If this does not fix the problem, replace the O-ring with a new Buna 70 O-ring size 225.

If you pump your instrument but the pressure does not stay in the chamber you might have a problem with the check valve inside. Symptoms will be that you stroke the chamber down but the air does not lock into the chamber. Instead the chamber wants to push back up. This means that the check-valve inside the chamber has been clogged. The valve needs to be removed, cleaned in soapy water and use some compressed air to blow through the check valve. This will normally clear any grease or debris keeping the check valve from closing. When re-installing be careful to just tighten the valve in lightly. This small valve will break off if over-tightened.

If you do not have a leak but your instrument will not increase in pressure try our tutorial “Instrument will not increase in pressure”